Technologies Settlement Temperature Fluctuations in Long Cable Trays

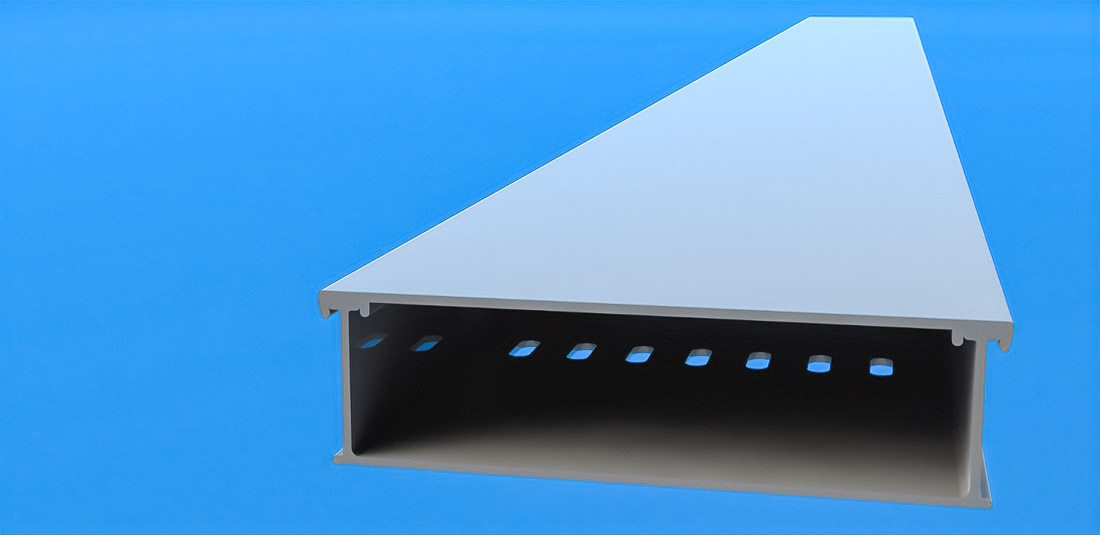

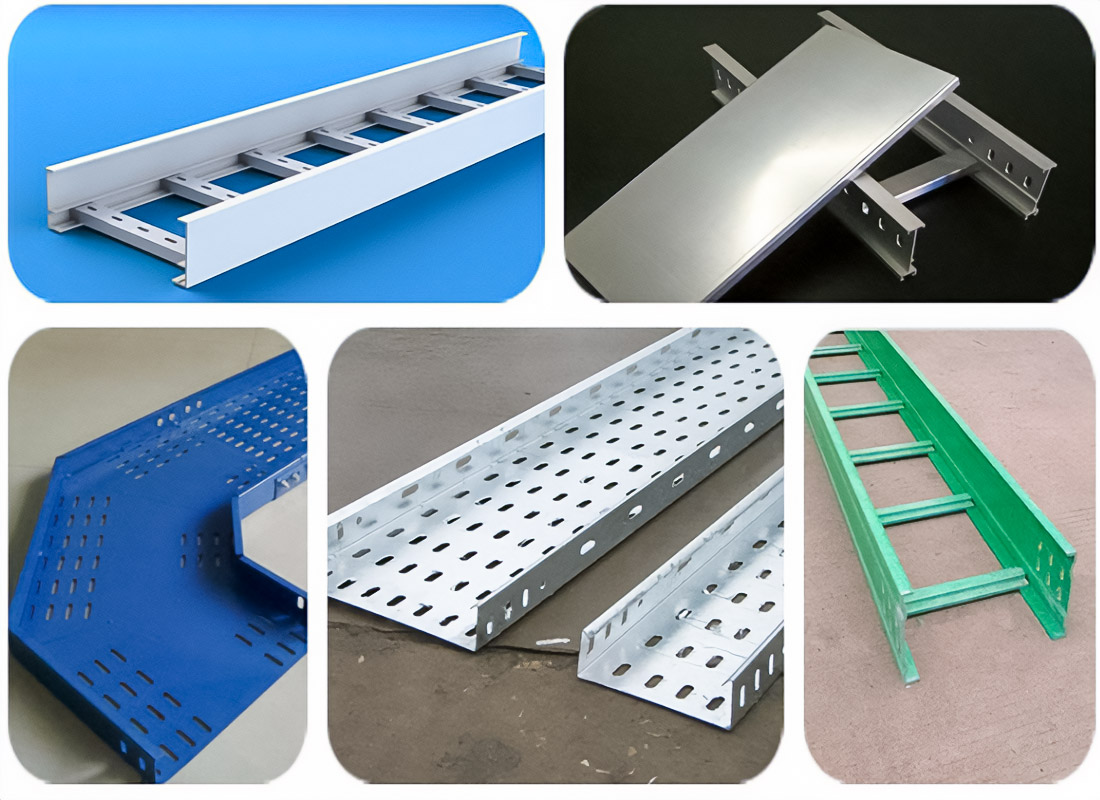

Long cable trays are constantly exposed to influence significant temperature changes. This phenomenon can occur under the influence of the external environment, such as climate changes, as well as internal factors, such as heating cables during the transmission of electricity. Such temperature fluctuations cause changes in the sizes of materials, which consist of trays. If these deformations do not compensate properly, they can provoke warping trays and damage cables, which inevitably will lead to the failure of the whole system. ladder cable tray offers wide selection solutions for such situations.

Dynamics Temperature Changes in Modern Cable Trays

Compensatory seams act as key component, allowing control temperature impacts. These seams give possibility materials freely expand and contract without damage for construction. As result, lifespan cable systems increases, and their reliability significantly increases, what minimizes risks occurrence accidents.

Categories Compensatory Seams and Their Significant Advantages

Exists several options for compensatory seams, suitable for installation in cable trays:

- Sliding seams: These seams provide an opportunity for one part tray to move relative to another. This is implemented by using modern guides and fastening systems. Sliding seams are most effective on extended straight sections, where temperature changes are significant. Application such type seams reduce the risk of damaged cables by 30%.

- Loop seams: They include various curved zones cable tray, facilitating expansion and contraction depending on temperature conditions. Loop seams are ideally suitable for complex sections with frequent changes in directions, providing compensation deformations in all planes. Research shows that loop seams reduce the load on fastenings by 25%.

- Compressed seams: Use elastic components, such as springs or shock absorbers, compressing or stretching at change temperature. They are often applied in combination with other types of seams for increased compensation. Efficiency compressed seams increase the stability of construction by 20%.

Each type of compensatory seam possesses unique advantages and can be adapted depending on conditions of operation and design features object.

Detailed Guide on Design and Installation Compensatory Seams

- Assessment operational conditions: Determine range temperature fluctuations. This can cover seasonal changes as internal impacts from cables. Together with changes in temperature, consider average level humidity and possible mechanical loads.

- Choice type seam: Emphasizing received data, choose optimal type seam. For trays lengths more than 50 meters, it is recommended to use sliding seams, whereas complex systems may require loop seams.

- Calculations deformations: Conduct detailed calculations for determination possible deformations. This will ensure correct selection sizes and tolerances for compensatory seams. Thermal expansion plays key role in such calculations.

- Design: Develop project, including detailed drawings and specifications. Consider international and national standards, such as IEC and GOST, for coordination projects with existing norms.

- Installation: Specialized installation teams must install seams in accordance with plans. Ensure their optimal placement and reliable fastening to minimize risk errors.

- Testing: Mandatory tests installed seams will allow checking their operability and compliance with project requirements. Quality testing reduces the likelihood of failures by 15%.

Successful Implementations and Their Results

Bright example successful application compensatory seams is project on large petrochemical complex. Here, in conditions high temperature and humidity, were chosen sliding seams. This solution allowed successfully compensate deformations and ensured reliable operation system more than 10 years.

Another successful project was – the modernization power plant, where applied loop seams were in places with frequent turns cable trays. Thanks to this, we managed to reduce the load on fastenings and prevent possible breakdowns by 40%. Electric power systems often face with such challenges.

Regulations and Advanced Methods Work

The design and installation of compensatory seams follow strict international standards IEC and ISO. Russia also considered GOSTs and SNiPs, regulating this process.

Among best practices include:

- Systematic monitoring condition seams.

- Application-certified materials and components.

- Training maintenance personnel in modern methods of installation and maintenance.

Potential Difficulties and Their Effective Solutions

During operation, compensatory seams can manifest various problems. Most common among them include wear or damaged elements, incorrect fastening, or non-fulfillment of project specifications. For prevention, these problems are necessary:

- Regularly conduct inspections and technical maintenance.

- Use exclusively certified elements.

- Follow project documentation without deviations.

Besides, important consider specifics work in aggressive environments or at increased loads, what may require application special materials or protective coatings.

Competent use compensatory seams guarantees significant increase reliability and longevity cable systems, ensuring their uninterrupted functioning even in most complex conditions operation. Such practice minimizes likelihood accidents and downtime, what directly affects increase efficiency operation objects.

Hockey fan, dreamer, record lover, Swiss design-head and screen printer. Producing at the sweet spot between aesthetics and function to craft delightful brand experiences. Concept is the foundation of everything else.

Long cable trays are constantly exposed to influence significant temperature changes. This phenomenon can occur under the influence of the external environment, such as climate changes, as well as internal factors, such as heating cables during the transmission of electricity. Such temperature fluctuations cause changes in the sizes of materials, which consist of trays. If…